.png&w=3840&q=75)

Count Print Finishing Machines: Creasing, Folding, and Scoring Done Right

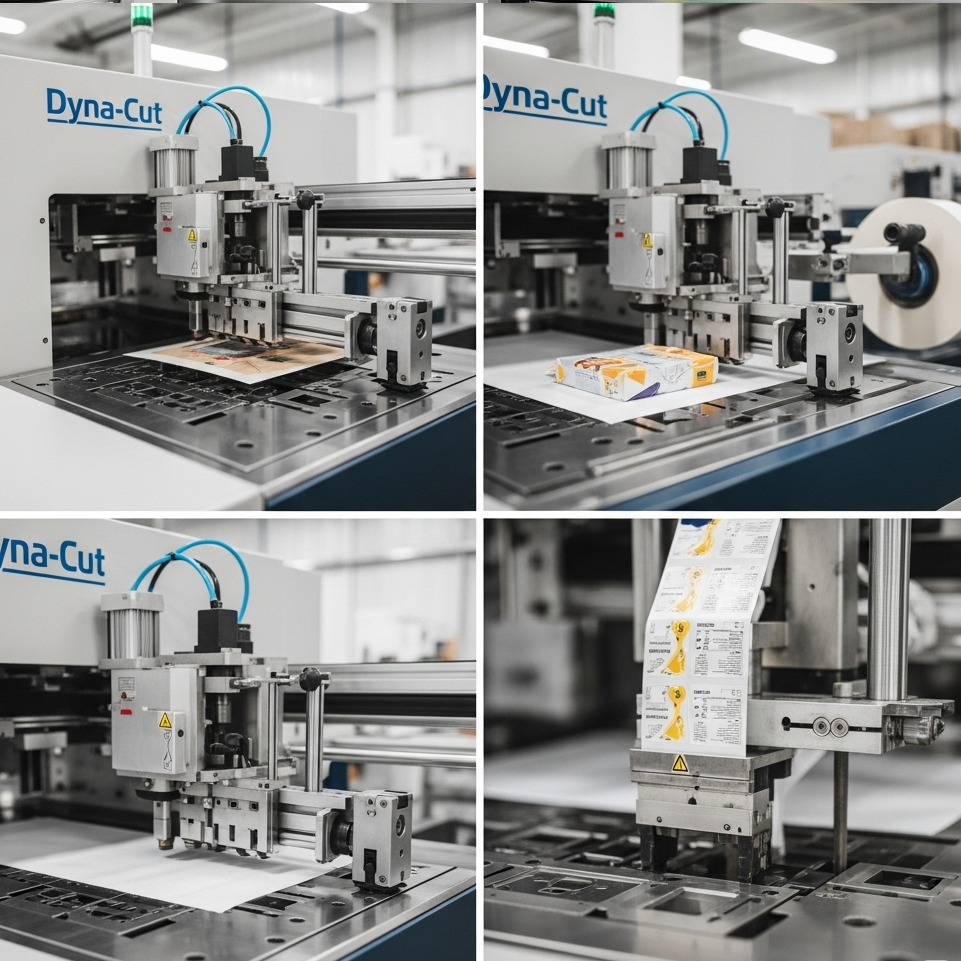

Packaging and labeling significantly influence how customers perceive a product. Accurate cuts and well-placed labels increase the visual appeal and enhance brand recognition. Any inconsistency or error in these processes can reduce customer confidence and negatively impact sales. Dyna-Cut’s die-cutting systems deliver the high precision needed to ensure products consistently look professional and polished.

Dyna-Cut offers machines capable of processing a variety of substrates including paper, film, foil, and synthetic materials. This adaptability allows companies to handle different product types with the same equipment. Whether producing adhesive labels, promotional stickers, or custom packaging inserts, Dyna-Cut machines can be quickly adjusted to meet specific production demands, boosting operational efficiency.

Automation is a core feature of Dyna-Cut systems. Functions such as automatic feeding, cutting, stacking, and waste removal reduce manual labor and minimize errors. This not only increases throughput but also helps maintain consistent quality throughout production runs. By automating repetitive tasks, businesses can save time and lower labor costs while producing more output.

Dyna-Cut equipment is utilized across multiple industries where precision cutting is essential. Packaging manufacturers rely on these systems to create custom boxes and business cards. Pharmaceutical companies use them to produce compliant, high-quality labels. The food and beverage sector applies them in packaging, while cosmetic companies depend on them for product labeling and branding. Additionally, promotional product manufacturers benefit from the ability to create detailed decals and stickers.

The modular design of Dyna-Cut machines allows businesses to scale their operations as needed. Companies can start with basic configurations and add additional features or modules as production requirements grow. This scalability provides flexibility and protects investments over time. Easy setup and user-friendly controls also ensure that operators can quickly switch between jobs and minimize downtime.

Dyna-Cut systems combine precision engineering with smart automation to help businesses improve packaging and labeling quality. Their reliable and adaptable equipment enables companies to deliver attractive, professional products that meet customer expectations and industry standards.